Climate Change and Carbon Neutral Initiatives

Basic Approach

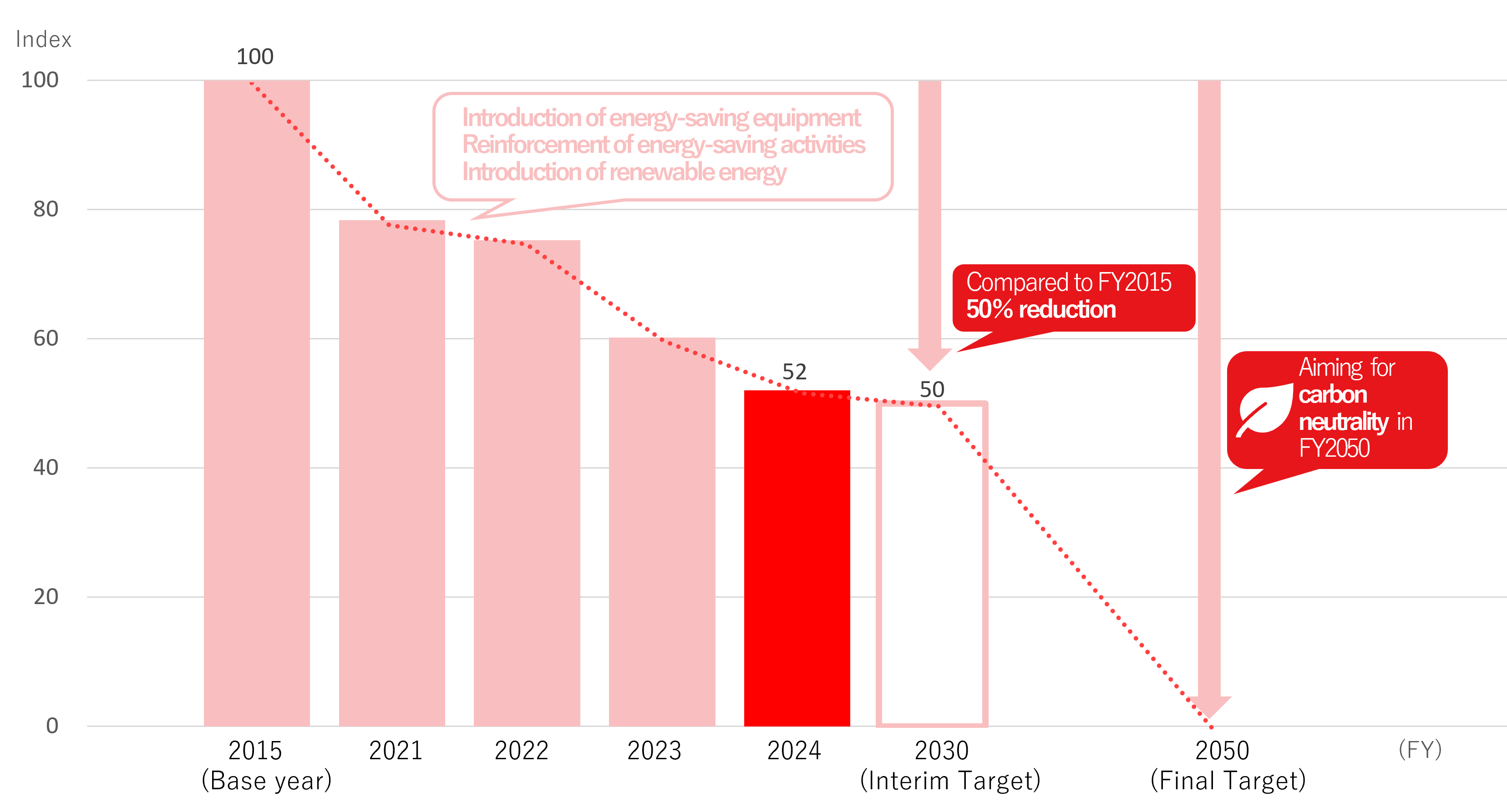

In order to contribute to materialize a decarbonized society, the KOITO Group is promoting the introduction of plant buildings and energy-saving manufacturing facilities that emit less CO₂ with the goal of achieving carbon neutrality (Scope 1 and 2) in FY2050. Furthermore, we are undertaking efforts to reduce CO₂ emissions throughout the product life cycle (Scope 3) as a company-wide initiative, promoting products' power conservation, size reduction, and weight reduction from the development and design phase.

Efforts in the Production Process

The KOITO Group is working to improve production methods and facilities, update facilities (introducing energy-saving equipment), switch to automatic power-off when not in use, and update to high-efficiency air conditioning units, etc., in order to save energy and improve production efficiency of the production process.

We are also working to achieve 50% reduction in CO₂ emissions (compared to FY2015) by FY2030 and carbon neutrality by FY2050.

Trends in Emissions (Scope 1 and 2) from Our Business Activities

| Data | Unit | FY2015 | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|---|---|

| Scope 1 and 2 | Thousand t-CO₂ | 542.9 | 425.2 | 408.6 | 326.7 | 284.3 |

*Calculated based on the GHG Protocol.

Efforts in the Supply Chain

The KOITO Group is undertaking efforts to reduce CO₂ emissions including strengthening partnerships with business partners, as well as making products more energy-efficient and lighter, in order to reduce CO₂ emissions across the supply chain, from raw material procurement to product use and disposal.

We have set a reduction target of 30% (compared to FY2018) by FY2030 for the two categories of scope 3, category 1 (purchased goods and services) and category 11 (use of sold products), aiming to promote the reduction of CO₂ emissions in the supply chain.

Trends in the Supply Chain Emissions (Scope3)

| Categories | Unit | Results | Target | ||||||

|---|---|---|---|---|---|---|---|---|---|

|

FY2018 (Base year) |

FY2021 | FY2022 | FY2023 | FY2024 | Remarks | FY2030 | |||

| 1 | Purchased goods and services | Thousand t-CO₂ | 2,537.7 | 2,302.8 | 2,556.5 | 2,824.6 | 2,634.5 | A reduction of 30% from FY2018 (Category 1, 11) |

|

| 2 | Capital goods | 199.9 | 123.2 | 157.5 | 158.0 | 157.6 | |||

| 3 | Fuel- and energy-related activities (not included in scope 1 or scope 2) |

65.5 | 42.7 | 36.0 | 37.1 | 34.4 | |||

| 4 | Upstream transportation and distribution | 42.7 | 37.9 | 44.1 | 49.7 | 50.2 | |||

| 5 | Waste generated in operations | 6.3 | 5.2 | 6.1 | 6.0 | 6.5 | |||

| 6 | Business travel | 4.6 | 2.8 | 3.0 | 3.3 | 3.3 | |||

| 7 | Employee commuting | 15.2 | 14.5 | 14.6 | 14.6 | 14.4 | |||

| 8 | Upstream leased assets | - | - | - | - | - | Included in Scope 1 and 2 | ||

| 9 | Downstream transportation and distribution | - | - | - | - | - | Included in Category 4 | ||

| 10 | Processing of sold products | - | - | - | - | - | N/A | ||

| 11 | Use of sold products | 1,572.5 | 1,026.1 | 1,055.2 | 1,047.1 | 959.7 | |||

| 12 | End-of-life treatment of sold products | 21.8 | 16.6 | 17.8 | 19.2 | 17.4 | |||

| 13 | Downstream leased assets | - | - | - | - | - | N/A | ||

| 14 | Franchises | - | - | - | - | - | N/A | ||

| 15 | Investments | - | - | - | - | - | N/A | ||

|

Total of Scope 3 (Consolidated) |

4,466.2 | 3,571.9 | 3,890.6 | 4,159.8 | 3,878.0 | ||||

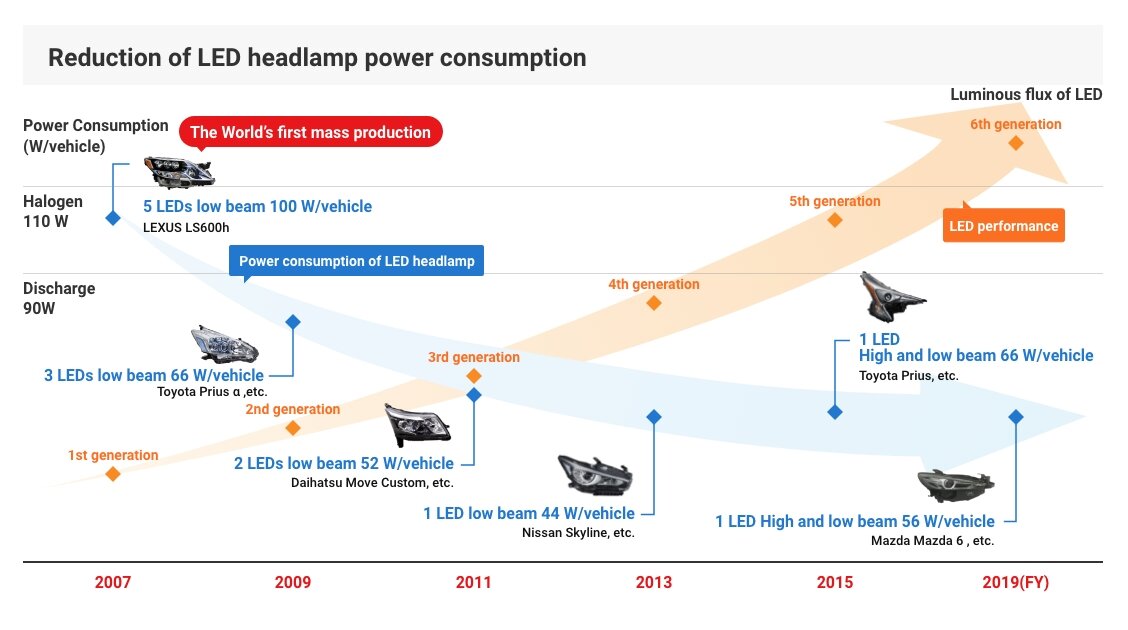

Efforts through Products (LED Headlamps)

KOITO has been working on the use of LED light sources for lamps before other companies to contribute to improved fuel efficiency and reduced CO₂ emissions in automobiles with more energy-efficient lamps. LED headlamps consume about 70% less power than conventional lamps and contribute to reducing the load on the battery.

Currently, the use of LED headlamps is expanding to a wide range of vehicles, from large vehicles to small vehicles, mini vehicles, and motorcycles, and in FY2023, the adoption rate of LED headlamps among the headlamps produced by the KOITO Group was approximately 80%, making them the dominant headlamps at present.

We will continue to work to reduce CO₂ emissions from vehicles by promoting further improvements in performance, as well as making products smaller and lighter.

LED Headlamp's Contribution on CO₂ Reduction

The KOITO Group is contributing to improve fuel efficiency and reduce CO₂ emissions by providing LED headlamps.

KOITO has evaluated our global environmental contribution of LED headlamps by comparing the amount of CO₂ emissions when using conventional headlamps.

Contributions are increasing year by year due to the spread of LED headlamps and the evolution of light sources.

| Unit | FY2019 | FY2020 | FY2021 | FY2022 | FY2023 |

|---|---|---|---|---|---|

| Thousand t | 218.3 | 287.0 | 373.8 | 465.5 | 558.1 |

The calculation of CO₂ reduction contribution is calculated based on our own mythology, which was developed with reference to the EU "Technical Guidelines for the preparation of applications for the approval of innovative technologies pursuant to Regulation (EC) No 443/2009 and Regulation (EU) No 510/2011" and the JAPIA "Guidelines for LCI Calculation Supplementary Provision 2 (Data Tables for Calculating Environmental Impact at Stage of Use) Version 2."

Calculation method: Power-saving effect* (W)/1.000 x gasoline/electricity conversion efficiency (ℓ/kWh)/alternator efficiency x CO₂ emission coefficient of fuel (tCO₂/ℓ) x annual driving hours of car (h) x percentage of time headlamps are used x number of vehicles in our group with LED headlamps.

*Difference in power consumption when halogen headlamps and LED headlamps are used

LED Rear Combination Lamps

KOITO has conventionally used incandescent light bulbs to rear combination lamps. However, as LED achieves smaller, lighter, more energy efficient, and longer life lamps, and it contributes to the improvement of the fuel efficiency and CO₂ emissions reductions of vehicles, LED rear combination lamps are also being adopted in various vehicles as in the case of LED headlamps.

Development of Smaller and Lighter Components

Through our collaboration between relevant divisions, development, design, production and procurement, KOITO is working to minimize and reduce the weight of our products by reducing the number of components and resinification to contribute to improve the fuel efficiency of automobiles.

Efforts in Logistics

The logistics of KOITO are mainly conducted by freight trucks.

One of our domestic subsidiaries, Koito Transport acquired the Green Business Certificate in February 2004. Collaborating with KOITO, Koito Transport aims to operate environmentally friendly transport business by reducing environmental impacts focusing on reducing the energy consumption, CO₂ emissions, and waste emitted through the logistics process.

The amount of CO₂ emissions from the entire logistics operation of KOITO was 12,300 tons in FY2021, and energy usage per unit* was 0.157 kl per billion yen.

* Energy usage per unit (kl / billion yen): Amount of energy (kl in crude oil equivalent) consumed in logistics per unit of sales (billion yen).

Koito Transport is gradually upgrading conventional trucks to four-axis trucks and optimizing operations by adopting long haul delivery. We are also working to improve safety by introducing studless tires. As a result of these efforts on environment and safety, Koito Transport has received a number of awards, including the Minister of the Environment's Award and the Minister of Land, Infrastructure and Transport's Award.

We will continue to pursue further eco-driving and strive to achieve safe and reliable operations and reduce CO₂ emissions.

Amount of CO₂ Emissions and Energy Usage per Unit in Logistics

| Data | Unit | FY2017 | FY2018 | FY2019 | FY2020 | FY2021 | FY2022 |

|---|---|---|---|---|---|---|---|

| CO₂ emissions in logistics | Thousand t-CO₂ | 13.4 | 13.9 | 14.0 | 12.8 | 12.3 | 12.3 |

| Energy usage per unit | ㎘/100 million yen | 1.48 | 1.44 | 1.48 | 1.54 | 1.57 | 1.56 |

* Energy usage per unit (kl / billion yen): Amount of energy (kl in crude oil equivalent) consumed in logistics per unit of sales (billion yen).