Environmental Management

Basic Approach

The KOITO Group declares in the "KOITO Group Corporate Behavior Charter," our basic policy for our corporate activities, that we will proactively engage in global environment conservation through our business activities, "guided by the theme of 'Eco-friendly Manufacturing for People and the Earth.'"

Based on this policy, KOITO has established the "Environmental Policy" which sets out the framework for our environmental activities and the implementation of this policy in the environmental management of all fields, from development to design, production, procurement, logistics, and more.

Our domestic and overseas subsidiaries have also established an "Environmental Policy" and built environmental management systems, meaning the promotion of environmental conservation activities extends throughout the KOITO Group.

Environmental Policy

KOITO MANUFACTURING CO., LTD. pursues "Eco-friendly Manufacturing for People and the Earth" in all of our automotive lighting-centered business activities, through the promotion of environmental conservation activities:

To clarify our targets and measures for environmental conservation and work continuously to improve the KOITO Group's environmental performance;

To formulate and promote environmental improvement plans by considering environmental issues in advance and complying with environmental laws and regulations;

To work to develop and establish new environmentally-friendly technologies and products throughout the product life cycle;

To minimize the environmental impact and use of resources and energy in the manufacturing process, promote environmental protection activities, and prevent environmental problems from occurring;

To actively promote human resources development to achieve our environmental targets.

Revised in April 2017

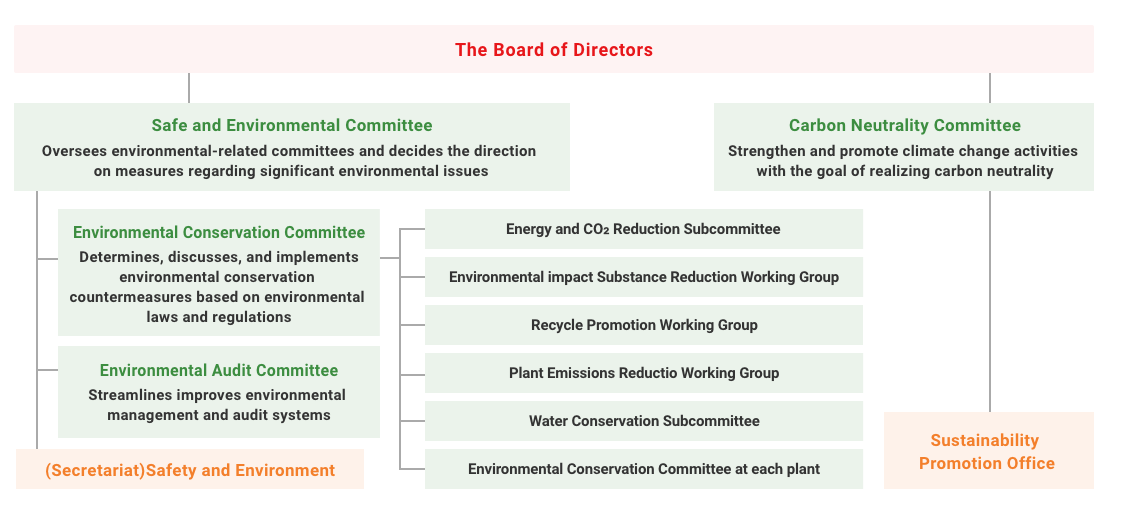

Management Structure for Environmental Activities

KOITO convenes the monthly Safe and Environmental Committee chaired by the Representative Director to supervise environmental activities of the entire Group and to discuss and make decisions on important environmental issues and environmental conservation measures to be implemented under environmental laws and regulations.

Subcommittees and working groups, such as the Energy and CO2 Reduction Subcommittee, Environmental Impact Substance Reduction Working Group, and Recycle Promotion Working Group, which were established to address specific environmental issues, are implementing specific activities.

These activities are reported to the Safe and Environmental Committee, which follows up on progress and discussing various actions.

Establishment of Environmental Management System

The KOITO Group is building the environmental management system for the entire Group. We are working to acquire ISO 14001 and other environmental certificates primarily at our manufacturing sites. As of the end of March 2023, a total of 24 companies out of 25 eligible for certification have acquired environmental certificates: 12 in Japan, including KOITO MANUFACTURING, and 12 overseas.

The KOITO Group also recommends major suppliers to acquire certificates, such as ISO 14001 and Eco-Action 21, in order to reinforce environmental management and conservation through the entire supply chain.

KOITO's ISO 14001 Certification in Production Sites

| Site | Year-month of initial registration |

The latest renewal date |

|---|---|---|

| Shizuoka Plant | January 2020 | January 2021 |

| Koito Parts Center | ||

| Haibara Plant | July 2000 | |

| Sagara Plant | ||

| Fujikawa Tooling Plant | January 2003 |

Scope of Environmental Management:

KOITO's environmental management is applied to the above five sites with respect to business activities related to the R&D, design, production, logistics, etc. of automotive lighting equipment, aircraft components and others. In addition, environmental impact arising from the product life cycle are also applied to the management.

Environmental Certificates Acquired in the KOITO Group

| Domestic subsidiaries | ||

|---|---|---|

| ISO 14001 | KOITO KYUSHU | Aoitec |

| Shizuokadenso | Nissei Industries | |

| Fujieda Auto Lighting | Shizuoka Wire Harness | |

| KOITO ELECTRIC INDUSTRIES | ||

| Eco-Action 21 | Haibara Machine and Tools | Shizuoka Kanagata |

| Takeda Suntech | ||

| Green Management Certificate | Koito Transport | |

| Overseas subsidiaries | ||

|---|---|---|

| ISO 14001 | North American Lighting (U.S.A.) | North American Lighting Mexico (Mexico) |

| NAL do Brasil (Brazil) | Koito Europe (U.K.) | |

| Koito Czech (Czech Republic) | GUANGZHOU KOITO (China) | |

| Hubei Koito (China) | FUZHOU KOITO TAYIH (China) | |

| THAI KOITO (Thailand) | INDONESIA KOITO (Indonesia) | |

| Ta Yih Industrial (Taiwan) | INDIA JAPAN LIGHTING (India) | |

Environmental Targets and Performance

To implement "Eco-friendly Manufacturing for People and the Earth" and promote environmental conservation activities effectively, KOITO has set quantitative medium-term targets and short-term targets every year for various indicators. The progress of activities is managed and the degree of achievement of targets is evaluated by the Safe and Environmental Committee and other bodies.

Environmental Management Plan and Results

| Environmental objectives | Priority efforts and performance in FY 2022 | Main approaches from FY 2022 | |||

|---|---|---|---|---|---|

| Priority | Target | Result | |||

| Management and reduction of chemical substances |

Contribution to low-carbon society | Reduction of CO₂ from production | CO₂ emissions intensity: 28% reduction from FY 2014 (amount of CO₂ emissions: 61,900 t- CO₂) |

23% reduction from FY 2014 (amount of CO₂ emissions: 56,700 t-CO₂) |

1. Reduction of energy use and CO₂ emissions in production activities - Amount of CO₂ emissions in FY 2031: 50% reduction from FY 2014 - Achieve carbon neutrality by FY 2051 2. Reduction of energy use and CO₂ emissions in logistics - Energy usage per unit: 1% reduction per year 3. Reduction of environmental impact substances in the product life cycle |

| Reduction of CO₂ from logistics | Energy usage per unit: 1% reduction per year |

1% increase from FY 2022 | |||

| Resource and water circulation | Development of recycle-oriented society | Reduction of the amount of waste |

Waste generated per unit: 4% reduction from FY 2019

*Set targets for industrial plastic waste in response to the Law for Promotion of Resources Recycling of Plastics

Basic unit:4% reduction from FY2019

Recycling rate:Maintain 85% or more

|

19% reduction from FY 2019 |

1. Development of recycle-oriented society

*Set targets for industrial plastic waste in response to the Law for Promotion of Resources Recycling of Plastics

Basic unit:4% reduction from FY2019

Recycling rate:Maintain 85% or more

|

| 14% reduction from FY 2019 More than 90% |

|||||

| Reduction of water consumption | Water usage per unit: 4% reduction from FY 2019 | 9% reduction from FY 2019 | |||

| Management and reduction of chemical substances |

Reduction of environmental impact substances | Reduction of VOC emissions | VOC emissions: Less than the amount in FY 2019 (299 t)Target for FY 2023: 220 tons or less | 173 tons (42% reduction from FY 2019) | 1. Reduction of environmental impact substances in production activities - Amount of VOC emissions: Maintain the amount below FY 2019 (299 tons) 2. Thorough management of environmental impact substances in products |

| Enrichment of environmental management | Reinforcement of globale environmental activities | Promotion of the reinforcement of consolidated environmental activities | Reinforcement of environmental risk management Thorough environmental compliance | Identification of potential risks and reinforcement of preventive measures (Identification of and response to near miss incidents) |

1. Reinforcement of the worldwide environmental management - Promotion of the reinforcement of consolidated management - Promotion of environmental activities with business partners (suppliers) - Proactive disclosure of environmental information and enrichment of communication - Reinforcement of environmental education 2. Development of society in harmony with nature - Promotion of biodiversity and nature conservation activities |

| Promotion of environmental efforts collaborating with suppliers | Promotion of aggressive environmental activities, improvement of environmental performance | Confirmation of management status and promotion of improvement through information sharing and on-site inspections | |||

| Disclosure of environmental information and enhancement of communication | Global disclosure of environmental information Promotion of mutual understanding with local communities | Disclosure of consolidated information Hosting round-table session with local communities | |||

| Reinforcement of environmental education | Promoting compliance, employee education and awareness-raising activities | Reevaluation of education structure for manager, supervisor and newly hiredemployees Implementing training for contractors (construction workers etc.) working in the premises |

|||

| Development of society in harmony with nature | Promotion of biodiversity and nature conservation activities | Promotion of activities at individual offices and regionsPromotion of biodiversity conservation activities | Cooperation with regional organizations and participation in activities with themReinforcement of activities to prevent global warming and effectively use resources | ||

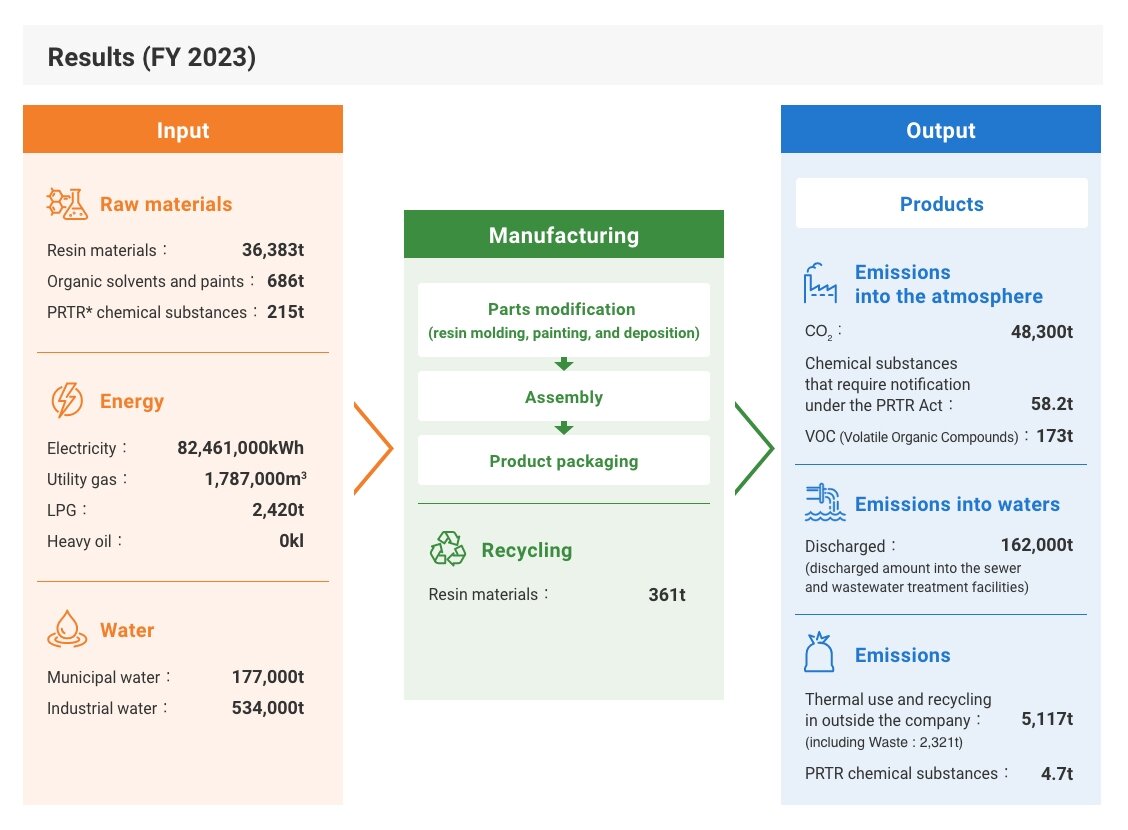

Material Balance

Energy and resource inputs and emissions (outputs) of greenhouse gas (GHG) and environmental impact substances such as VOC (Volatile Organic Compounds) in KOITO's business activities are as follows.

KOITO keeps track of the material balance in its business activities to verify and evaluate activities to reduce the environmental load and to use the data for the establishment of future measures.

※PRTR Law: Law Concerning Reporting, etc. of Releases to the Environment of Specific Chemical Substances and Promoting Improvements in Their Management

Environmental Audits

KOITO conducts annual external environmental audits and internal environmental audits to check the operational status of the environmental management system. Improvement proposals are prepared and implemented to respond to the aspects identified through those audits to maintain and operate the proper management system.

External Environmental Audits

A registered external accreditation firm checks whether the environmental management system has been properly established and operated based on ISO 14001.

Internal Environmental Audits

To ensure the independence of internal environmental audits, an audit team composed of internal auditors other than the department being audited is organized, and audits are conducted based on ISO 14001. The internal auditors are also conducting audits at their departments for continuous improvements and enhance environmental awareness.

Environmental Education

KOITO has established an education system and periodically provides environmental education to promote training for human resources to achieve our environmental targets as stated in the Environmental Policy and help every employee gain a deep understanding of the environment.

In addition to education for specific job ranks, such as new employees, managers, and supervisors, KOITO provides special education for internal auditors and promote our employees' acquisition of official licenses and qualifications. Meanwhile, June and July of every year are designated as KOITO Environmental Months during which employees participate in local clean-up activities and practice intensive environmental inspection to enhance the awareness of every employee.

KOITO provides education on preventing contamination and spillage to workers on the premises of KOITO, such as contractors, to enhance their awareness and prevent environmental accidents.

Safety and environmental education for the work conducted within the premises (2019)

Education for internal environmental auditors (2019)

Efforts throughout Supply Chain

Procurement policy briefing session (2019)

KOITO is committed to promote measures to reduce environmental load based on the comprehensive perspective of the product life cycle to coexist with global environment and local communities and to engage in environmental activities through all business activities, including green procurement of raw materials, parts and equipments.

Aiming to materialize a sustainable society, KOITO is working to strengthen supply chain management. We hold annual procurement policy briefing session and monthly information liaison meetings for suppliers to encourage them to acquire environmental certifications, such as ISO 14001 and Eco-Action 21, and request compliance with environmental laws and regulations on environmentally hazardous substances.

In FY 2022, KOITO held a supplier meeting on May 17, 2021 and 204 suppliers attended it.

Environmental Laws and Regulations Compliance Status

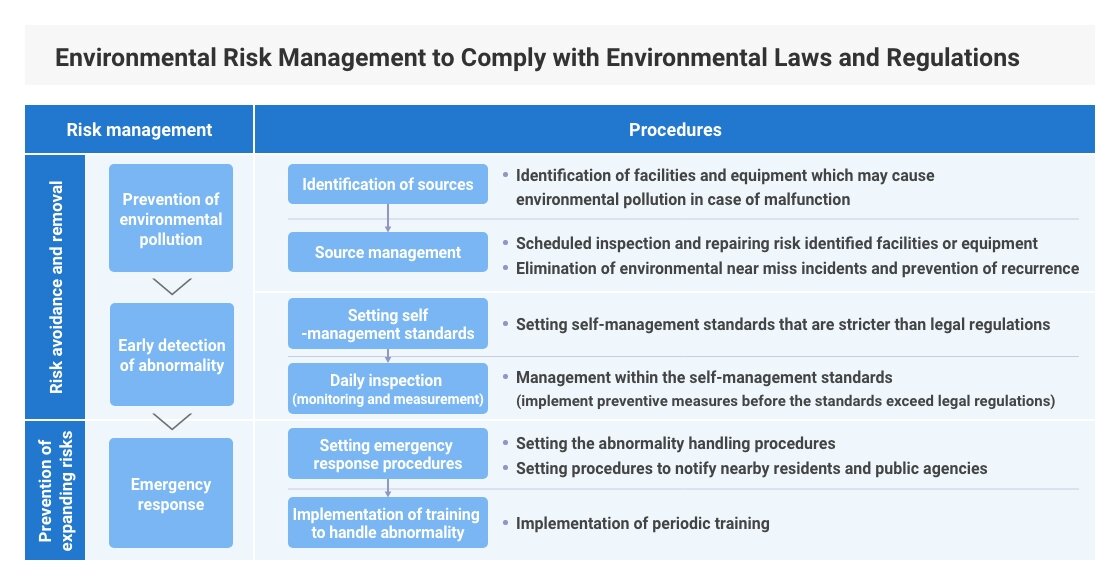

KOITO conducts thorough risk management, such as specifying the sources of environmental risks, detecting abnormalities in the early stages through regular measurements, and establishing emergency response measures to minimize environmental risks by complying with environmental laws and regulations, such as ones to prevent air pollution, water contamination and soil contamination.

Through these risk management activities, KOITO makes sure that emissions, water quality, noise, and soil and groundwater contamination are within the ranges permitted under laws, regulations, and standards. In FY 2022, neither violations of environmental laws and regulations nor fines were reported at the KOITO Group.

The KOITO Group is committed to compliance with environmental laws and regulations, and continue to work on environmental risk management.