Quality and Product Safety

Basic Approach

The KOITO Group declares in the KOITO Group Corporate Behavior Charter that "we will gain customers' satisfaction and trust through developing and providing safe and high-quality products and services," and identified "enhancement of product quality" as one of our materialities. We strive to create products with a customer-first attitude to maintain and further improve quality of all products and services we provide to our customers.

The KOITO Group is utilizing its Quality Management System (QMS) to maintain and supervise the quality level in all kinds of departments, from development to production.

We will continue quality assurance activities to meet the situations in various countries or regions and will keep contributing to materialize a sustainable society through maintenance and improvement of the product quality.

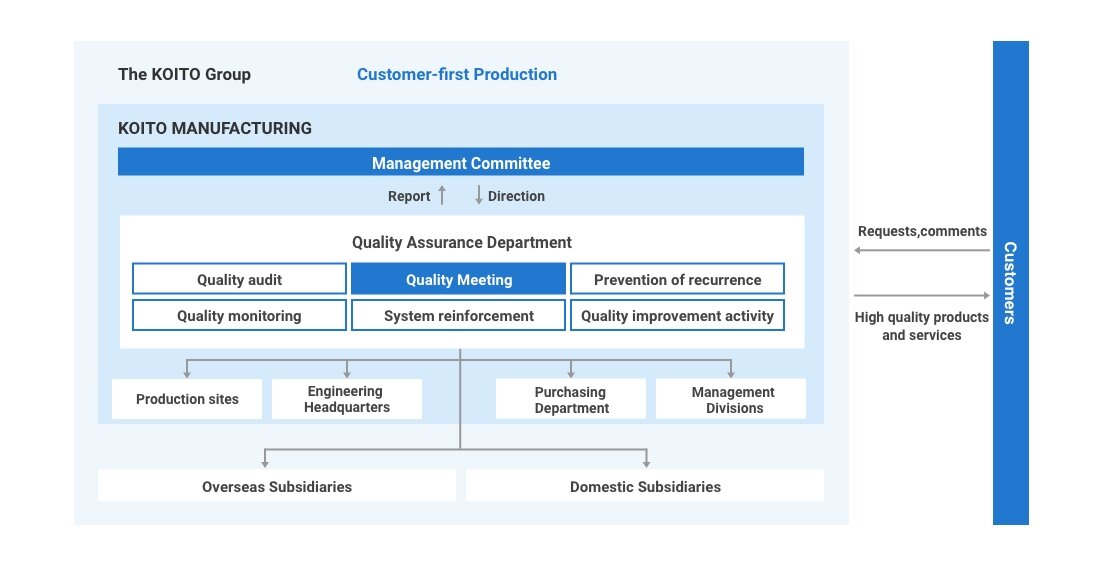

Quality Management Structure

KOITO has established a quality management system based on ISO 9001 and IATF 16949 which are international standards to ensure seamless operations.

Internal Quality Audits with the Quality Assurance Manager as the chair are conducted at least once every year to make decisions on the quality management aspects and to monitor the quality management status of the entire KOITO Group. The Internal Quality Audit Office with qualified internal quality auditors as the main members is carrying out specific activities.

The progress of these activities is reported to the Board of Directors and Managing Committee by Director or Corporate Officer who are in charge of Quality Assurance Department to reinforce the management system through monitoring by the management. KOITO is going to further reinforce the establishment of the quality assurance system by building a global system to perform quality tests and evaluations. KOITO is building a system to find the causes of any defects found and implement prevention measures in case any defects are found through quality tests and evaluations.

Regarding the notification of a recall in the event of a market defect in our products, KOITO works with our customers to determine the impact on safety, interpret safety standards, and take other measures promptly and appropriately. KOITO also has a system in place to implement thorough measures to prevent a recurrence.

Acquisition of Quality Management System Certificates

The following is the list of Group companies, including overseas subsidiaries, that have acquired ISO 19001 or IATF 16949.

All the subsidiaries and departments of KOITO will continue to carry out a thorough PDCA cycle, and ensure product safety and quality through enhancement of the quality management system.

| Obtained IS09001 certification | IATF16949 |

|---|---|

| KOITO KYUSHU LIMIED |

North American Lighting, Inc. |

| Aoitec Co., Ltd. |

North American Lighting Mexico, S.A. de C.V. |

| Shizuokadenso Co., Ltd. |

Koito Europe Limited |

| Nissei Industries Co., Ltd. |

Koito Czech s.r.o. |

| Fujieda Auto Lighting Co., Ltd. |

GUANGZHOU KOITO AUTOMOTIVELAMP CO., LTD. |

| Shizuoka Wire Harness Co., Ltd. |

Hubei Koito Automotive Lamp Co., Ltd. |

| KOITO ELECTRIC INDUSTRIES, LTD. |

FUZHOU KOITO TAYIH AUTOMOTIVE LAMP CO., LTD. |

THAI KOITO COMPANY LIMITED |

|

PT. INDONESIA KOITO |

|

Ta Yih Industrial Co., Ltd. |

|

INDIA JAPAN LIGHTING PRIVATE LIMITED |

Efforts in Quality Improvement

Staff QC Meeting (2019)

KOITO provides job rank-based quality education for new employees, managers, and supervisors. In addition, KOITO holds training session on SQC (Statistical Quality Control) for design and development engineers to improve their knowledge on quality management.

Furthermore, the QC circle activities and improvement presentation sessions (FQC Meeting, Staff QC Meeting and others) are being held periodically to improve quality management activities.

KOITO will continue to enrich activities on training and education to further improve quality.